Factory Environment Management System

Challenges in Factory Environmental Management

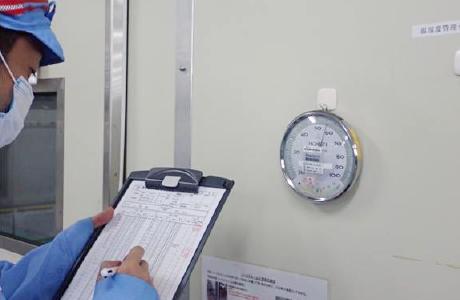

As a semiconductor assembly plant specializing in back-end processes, we maintain strict temperature and humidity control. Currently, our staff manually checks the temperature and humidity readings twice a day to monitor for any abnormalities. Additionally, supervisors manually input data to track trends, resulting in a significant workload for management operations.

Automated Temperature and Humidity Monitoring System for Enhanced Factory Management

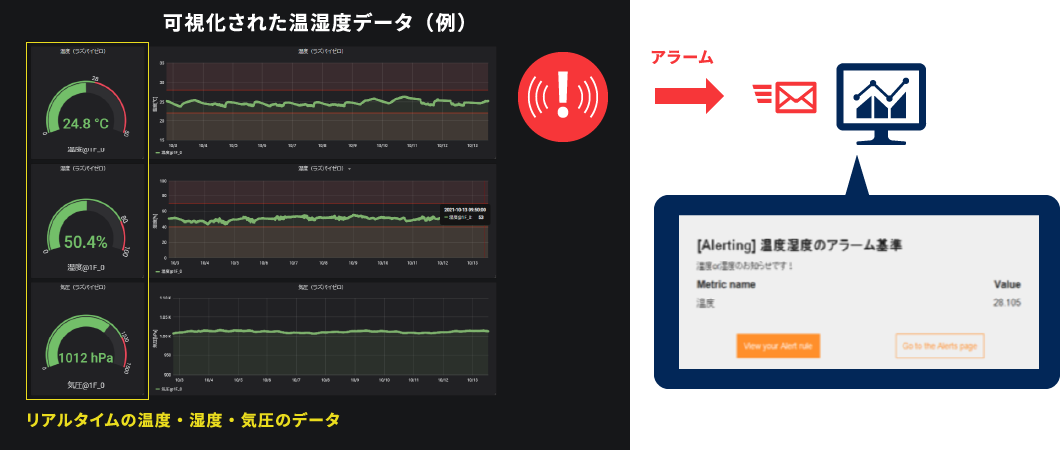

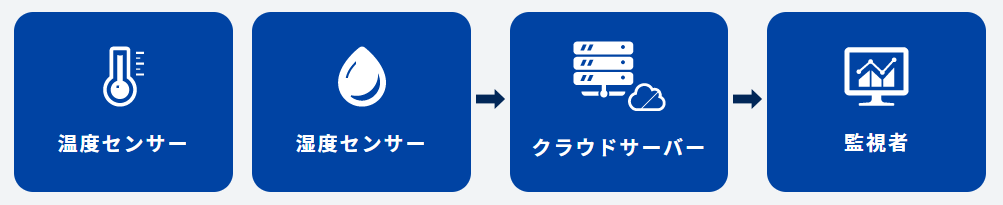

We have developed and implemented a comprehensive monitoring system by installing temperature and humidity sensors throughout the factory. This system automatically records environmental data, allowing supervisors to conveniently track both real-time conditions and historical trends on their computers without the need for manual input.

Furthermore, to enhance factory safety and efficiency, we have incorporated an alert function that immediately notifies staff when temperature or humidity levels exceed predefined thresholds. This enables a swift response to potential environmental abnormalities, ensuring a stable production environment and reducing the risk of issues caused by fluctuating conditions.