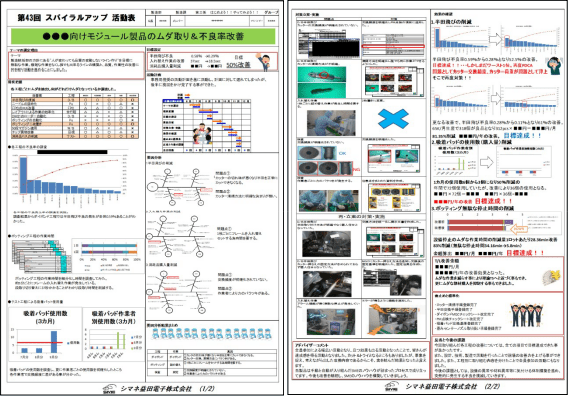

The Quality Assurance Department takes the lead in conducting regular activities across all departments (once a week). Based on the principle of "input materials are output as 100% good products," we are promoting improvement activities aimed at reducing and ultimately eliminating defects within the process.

Activity Example

In the initial stages of the activity, the yield distribution of a certain product assembly was scattered. After focusing on improving the die-bonding process (such as improvements to equipment and mechanisms), the yield distribution gradually concentrated toward the 100% side over the course of four years, resulting in an ideal outcome.

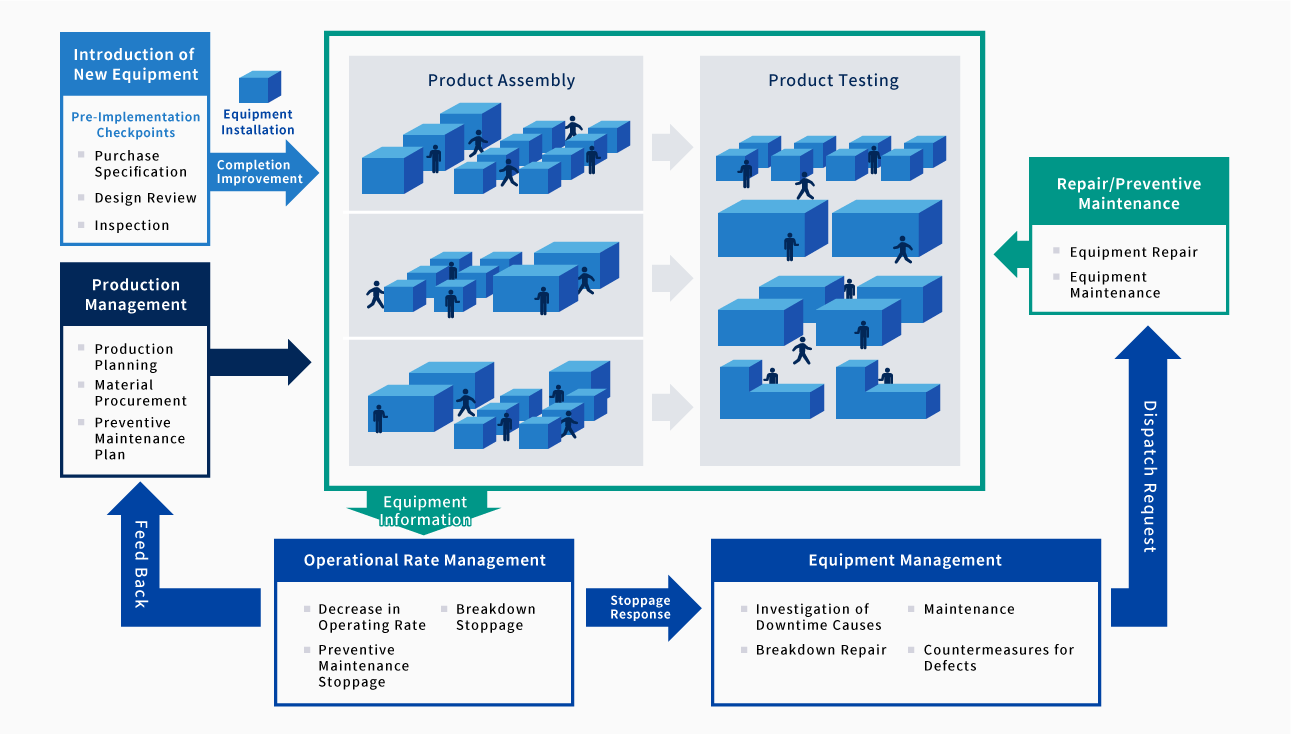

Activity Overview

In addition to discussions in the conference room, we conduct improvement activities based on the "Gemba" (3G) principle, where we confirm the actual site, material, and conditions. Engineers and operators are involved in the process as we work together to implement improvements.