Wafer Dicing

The wafer dicing process involves cutting semiconductor wafers, which contain integrated circuits, into individual chips using a dicing saw or other cutting methods.

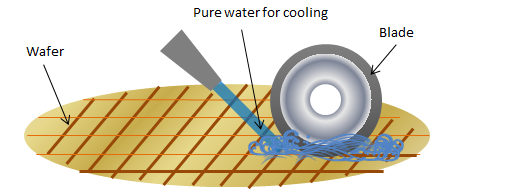

At our company, we utilize blade dicing, where wafers affixed to an adhesive sheet are cut into separate pieces using a high-speed rotating circular blade. Since the rotating blade generates heat, pure water is continuously supplied during the cutting process for cooling.

We carefully select the most suitable blade and cutting conditions based on the wafer’s material and thickness to minimize chipping and cracking around the cut edges, ensuring high-precision dicing services tailored to our customers’ needs.

The technology of Wafer Dicing

Our wafer dicing technology can handle wafer materials such as Si, GaAs, and InP, and we can process wafers up to 12 inches in size. In addition to wafers, we also accept re-dicing of pre-separated chips and dicing of non-standard-shaped wafers.

Evaluation of Wafer Dicing

Using stereo microscopes and metallurgical microscopes, our skilled operators visually inspect the wafer cutting areas for any chipping or cracking. Additionally, we use metallurgical microscopes for precise dimensional measurements.

Wafer Dicing Achievements and Advancements

We have over 30 years of experience and accomplishments in wafer dicing processing, starting with scribing. We have processed more than 40,000 wafers to date, and our high level of technical expertise and quality have earned the trust of many customers, including major electronics manufacturers. Additionally, we have maintained long-term relationships with customers who only request wafer processing, and our specialization is widely recognized.

Difference from Competitors

Our company is fully equipped with dedicated wastewater treatment facilities for handling compound materials, and we have extensive experience in processing special materials, such as GaN, SiC, and GaAs, which are often difficult for other companies to handle.

*We use a blade dicing method, which generates cutting debris. When processing compound materials, special attention is required for the cutting debris flowing with the water.

This ensures that we maintain strict environmental protection and legal compliance, while achieving safe and efficient processing.

Equipment Lineup of Wafer Dicing

- ・DFD620 (Disco Corporation) Blade Dicing

- ・DFD651 (Disco Corporation) Blade Dicing

- ・DFD6340 (Disco Corporation) Blade Dicing

We will solve your problems.

We specialize in handling highly confidential products and expensive materials, and we respond to our customers' needs in various ways. With the expertise gained from over 2,500 prototype projects, we can effectively solve your problems. We are also capable of handling small-batch production and accept orders starting from just one unit. Please feel free to reach out to us with any concerns or inquiries.

With the expertise gained from over 2,500 prototype projects, we provide comprehensive support to our customers

-

Capable of both automated and manual assembly

Capable of both automated and manual assembly

-

Trusted with all semiconductor-related tasks

Trusted with all semiconductor-related tasks

-

Collaborating with customers from product development onwards

Collaborating with customers from product development onwards

-

Customizing products based on customer specifications

Customizing products based on customer specifications

-

Offering one-stop service from product development to mass production, including material procurement

Offering one-stop service from product development to mass production, including material procurement

-

Treating custom products as if they were standard items

Treating custom products as if they were standard items