Underfill

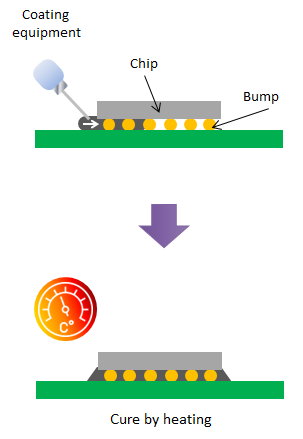

The underfill process involves the application of liquid epoxy resin (underfill material) between the substrate and the integrated circuit (semiconductor chip) mounted on the substrate in a flip-chip process. The resin is drawn into place by capillary action to reinforce the bond between the circuit and the substrate, preventing the electrodes from detaching.

Underfill serves to reduce external stress and prevents stress concentration at the junction between the substrate and the integrated circuit. Additionally, it helps to distribute the stress caused by the differences in the thermal expansion coefficients of the substrate and the integrated circuit, thereby improving the reliability of the product.

We carefully select the most suitable underfill material for the product specifications and provide high-quality underfill technology services while considering work efficiency. We also offer services for prototype development, small lot production, and short lead times.

The technology of Underfill

Our underfill technology is capable of filling gaps as small as 45μm or less between the integrated circuit and the substrate. Additionally, we can precisely control the application of the underfill to prevent it from flowing up onto the surface of the integrated circuit.

We also provide partial underfill services, such as applying underfill to solder joints of passive components like resistors and capacitors, ensuring that specific areas are addressed as needed.

Evaluation of Underfill

We offer various evaluations, including the observation of voids through cross-section polishing. Additionally, in collaboration with our partner companies, we provide non-destructive testing, such as ultrasonic deep crack testing (SAT).

Void inspection

We use a grinding system to slice the cross-section of the junction between the integrated circuit and the substrate for observation, photography, and measurement. We check for bonding defects such as voids in the underfill. By physically exposing the cross-section of the sample, we can observe fine abnormalities that are difficult to detect with non-destructive testing and examine the internal structure of components that X-rays cannot penetrate.

Equipment Lineup of Underfill

- TAD1000 Jet Dispensing Type

- FAD320S Air Dispensing Type

We will solve your problems.

We specialize in handling highly confidential products and expensive materials, and we respond to our customers' needs in various ways. With the expertise gained from over 2,500 prototype projects, we can effectively solve your problems. We are also capable of handling small-batch production and accept orders starting from just one unit. Please feel free to reach out to us with any concerns or inquiries.

With the expertise gained from over 2,500 prototype projects, we provide comprehensive support to our customers

-

Capable of both automated and manual assembly

Capable of both automated and manual assembly

-

Trusted with all semiconductor-related tasks

Trusted with all semiconductor-related tasks

-

Collaborating with customers from product development onwards

Collaborating with customers from product development onwards

-

Customizing products based on customer specifications

Customizing products based on customer specifications

-

Offering one-stop service from product development to mass production, including material procurement

Offering one-stop service from product development to mass production, including material procurement

-

Treating custom products as if they were standard items

Treating custom products as if they were standard items