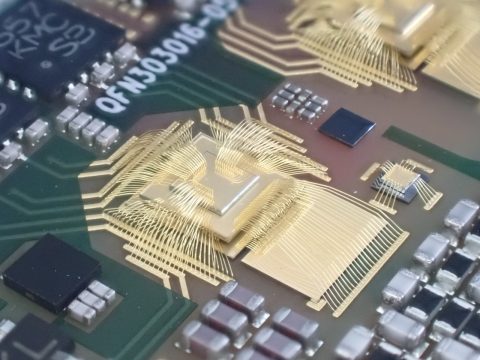

Wire Bonding

The wire bonding process is a method of electrically connecting the electrodes of an integrated circuit to the electrodes of a circuit board using metallic wires such as gold (Au), aluminum (Al), or copper (Cu).

Before wire bonding, the electrode surfaces are cleaned using plasma treatment (RIE mode) to remove organic contaminants, oxides, and other bonding inhibitors. This process minimizes bonding and adhesion defects caused by electrode surface abnormalities, reducing issues such as pad non-attachment and bond lifting.

SME offers a comprehensive wire bonding service, including program creation, jig/tooling design, and manufacturing optimized for product specifications. We accommodate prototype development, small-lot production, and short lead times to meet our customers’ needs.

We also provide wire bond repair (rework) services. On-site operations with customer supervision can be arranged upon request. Please feel free to contact us for further details.

Wire Bonding attachment

Our wire bonding technology supports the following wire types:

・Gold wire (15–30μm)

・Aluminum wire (100–300μm)

・Copper wire (15–30μm)

We can handle various substrates, including:

・Lead frames

・Ceramic substrates

・Glass epoxy (FR-4) substrates

・Flexible printed circuits (FPCs)

We also offer high-density wire bonding, precise wire length control, and wire bonding on both sides of a substrate.

Other materials are also available upon request.

Evaluation of Wire Bonding

We provide loop pull strength measurement to evaluate loop strength using a bonding tester, as well as shear strength measurement to assess the bonding strength between the wire and pad using shear force.

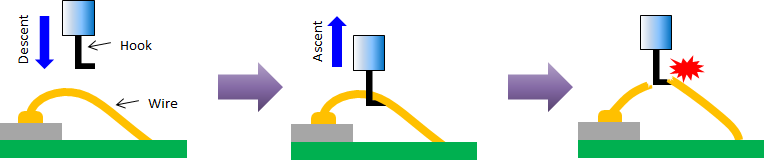

Loop Pull Strength Test

A hook attached to the load sensor of the bonding tester is hooked onto the wire. The hook is then lifted to break the wire, and the load value at the time of breakage is measured.

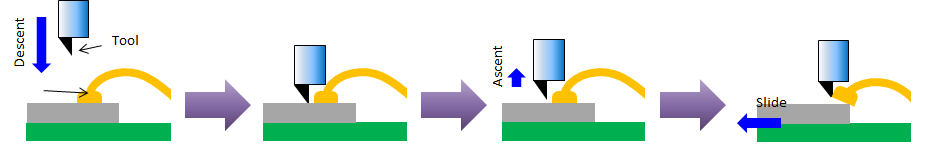

Shear Strength Test

The tool attached to the load sensor descends to the substrate surface, and the system detects the substrate surface and stops the descent. After detecting the substrate surface, the tool ascends to the set height, slides the substrate, and presses the joint to break it. The load at the moment of breakage is then measured.

Equipment Lineup of Wire Bonding

- UTC-3000 Series Method: Ball Bonding

- UTC-2000 Series Method: Ball Bonding

- UTC-1080 Series Method: Ball Bonding

- URB-4 Series Method: Wedge Bonding

We will solve your problems.

We specialize in handling highly confidential products and expensive materials, and we respond to our customers' needs in various ways. With the expertise gained from over 2,500 prototype projects, we can effectively solve your problems. We are also capable of handling small-batch production and accept orders starting from just one unit. Please feel free to reach out to us with any concerns or inquiries.

With the expertise gained from over 2,500 prototype projects, we provide comprehensive support to our customers

-

Capable of both automated and manual assembly

Capable of both automated and manual assembly

-

Trusted with all semiconductor-related tasks

Trusted with all semiconductor-related tasks

-

Collaborating with customers from product development onwards

Collaborating with customers from product development onwards

-

Customizing products based on customer specifications

Customizing products based on customer specifications

-

Offering one-stop service from product development to mass production, including material procurement

Offering one-stop service from product development to mass production, including material procurement

-

Treating custom products as if they were standard items

Treating custom products as if they were standard items