01

Business Description

What is EMS?

EMS, or Electronics Manufacturing Service, is a term widely used in the manufacturing industry. It refers to services that handle the manufacturing of electronic devices, as well as the companies providing such services.

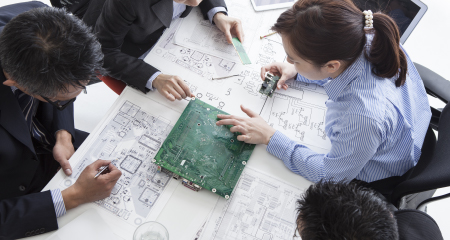

We distinguish ourselves from the traditional EMS (Electronics Manufacturing Service) model, which focuses on the production of semiconductors and electronic devices, by placing the DMS (Design, Development & Manufacturing Service) model at the core of our business.

Specifically, we provide comprehensive support throughout the entire product lifecycle, from initial concept design to detailed circuit and mechanical design based on customer requirements, prototype manufacturing and evaluation, and finally establishing a mass production system.

This approach not only enables our customers to shorten development timelines and improve cost efficiency but also enhances product quality and accelerates time-to-market.

A particular strength of the company is its emphasis on being involved in the product design phase and optimizing the design for manufacturing. This approach results in robust systems that minimize potential problems and risks during mass production.

Furthermore, we also function as an OSAT (Outsourced Semiconductor Assembly and Test) provider, offering comprehensive support for semiconductor assembly and testing processes. This allows us to cover the entire manufacturing process of semiconductor products, including wafer separation, packaging, electrical testing, and reliability verification, thereby addressing the diverse needs of our customers.