Case 01

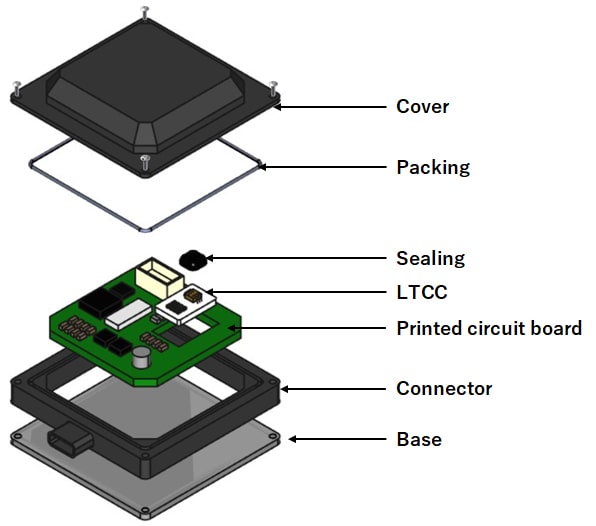

We are capable of assembling complex modules that involve component mounting, wire bonding, and encapsulation on printed circuit boards (PCBs) and ceramic substrates. We also support small-lot production starting from a single unit.

To meet our customers' requirements, we deliver custom products with flexibility by fully utilizing our manufacturing processes, methods, experience, and technology. Leveraging our accumulated expertise, we strive to bring each unique vision to life. There are product achievements that cannot be disclosed due to an NDA, so please contact us first.

We are capable of assembling complex modules that involve component mounting, wire bonding, and encapsulation on printed circuit boards (PCBs) and ceramic substrates. We also support small-lot production starting from a single unit.

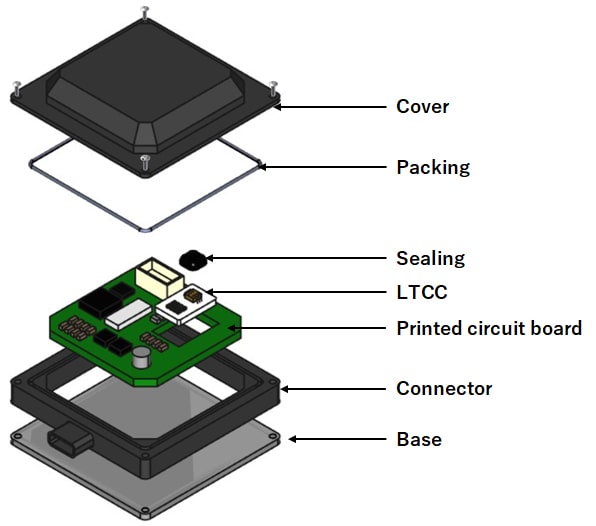

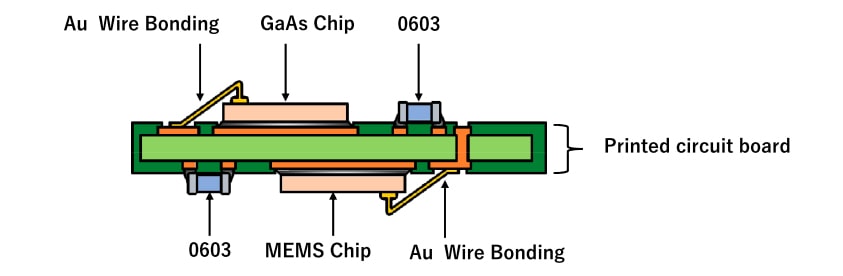

By combining solders with different melting points, we enable assembly without re-melting. After mounting the lead frame onto the printed circuit board (PCB), ICs and various components can be sequentially assembled while ensuring reliable fillet formation without melting previously formed solder joints. Additionally, we select the optimal materials to meet product specifications.

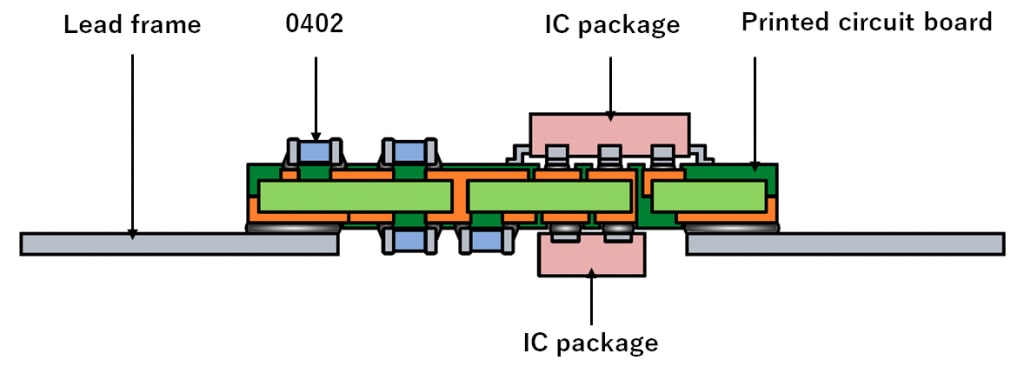

We can accommodate underfill for high-difficulty areas. After mounting chips on various substrates, we perform high-precision underfill using jet dispensing for products that require precise work within extremely small inlets or confined spaces.

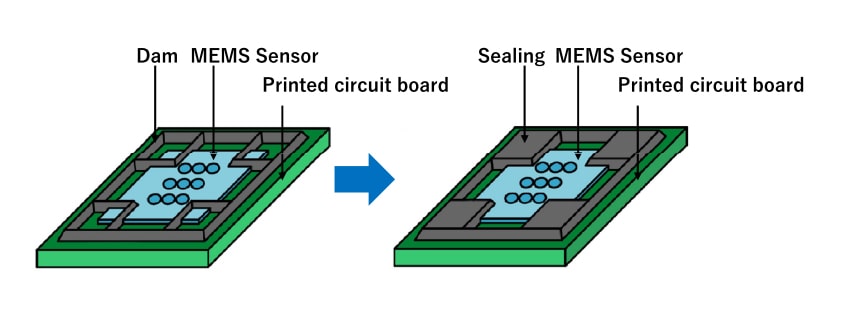

We can accommodate special shapes and partial encapsulation. After mounting MEMS sensors on the printed circuit board (PCB), we form a dam structure and apply precise encapsulation, ensuring a high-quality finish.

We are capable of die bonding, wire bonding, and surface mount component assembly on both sides of the printed circuit board (PCB). Additionally, we design the necessary tooling in-house, ensuring the delivery of high-precision products.

PAGE TOP